SMAR - Presents Innovation to the Biofuel and Biomass Industry duringFEW 2009 Fuel Ethanol Workshop Denver, CO

Every year in June (USA) and September (Brazil) the worlds leading ethanol technicians, scientists, suppliers and producers come together for the industrys pinnacle events to educate, improve processes, network, buy, and sell. As world ethanol production surges forward important event like the FEW 2009 (Fuel Ethanol Workshop) held in Denver, Co - continues to provide the platform on which the industry is built, grows, and prospers. SMAR International is proud to be part and a leader in this industry, presenting innovation and solutions for biofuel plants worldwide.

SMAR's associates Ernani Verissimo and Tony Andres with Anderson Control Reps Paula Tochen-Bell and Kevin Anderson

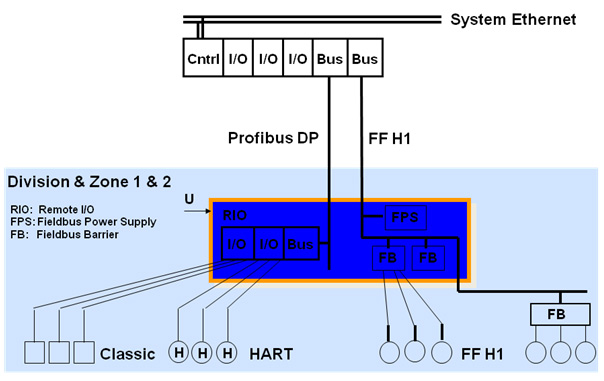

SYSTEM302 DEMO Co-existing with other platforms

- Traditional IO integrated with Fieldbus technology and Hart and Profibus.

- Ease of Integration across platform technologies while maintaining existing IO.

- Migration of IO from the field Junction Panel thru replacement of the terminals with remote IO.

- The Remote IO can replace a 24x24 field junction panels IO dependent on the mix of IO without having to replace the panel only the subpan

- Globally certified Hazardous Location Solutions (IEC,NEC IECex, etc)

- Supports Multiple protocols (Profibus, Fieldbus, Modbus TCP)

- Utilization of latest technologies for Hazardous Location installations

- Reduced installation costs -> from cable size and quantity reductions

- Combined expertise in providing Control integration with Hazardous location knowledge.

- SYSTEM302 DEMO demonstration in partnership with STAHL solutions.

Anderson Controls Principals Paul Anderson and Kevin Anderson

SMAR Solutions and control strategies allow biofuel producers to reap the benefits of new processing techniques and advanced control strategies.

For more than three decades, SMAR has been the unsurpassed leader in process automation solutions for the Ethanol industry. Our control systems and instrumentation, in use at the worlds largest ethanol production facilities, provide customers with greater reliability, reduced complexity, lower costs, increased flexibility, and improved scalability.

In Brazil sugar and ethanol markets alone, SMAR provided over 90% of all process control equipment currently in service. Applications are spread all over the plant, from the juicers to distillation or crystallization.

SMARs product portfolio goes from Management Info, Asset View, Control to Field Devices. Recognized as First in Fieldbus, we offer products based on recognized standards such as the HART (4-20mA), FOUNDATION fieldbus and PROFIBUS protocols. Our open SYSTEM302-7 architecture liberates users from the constraints of closed, proprietary systems; restores single-loop integrity and redundancy, and enables a field-centric control strategy throughout the Ethanol facility. SMAR products and software architecture are based on OPC, allowing integration of other bus technologies, legacy DCS, and proprietary subsystems.

Protecting Legacy Investments During Migration to New Control Technology

Ethanol and Bio-diesel plants around the world have implemented a practical, cost-effective solution for converting their existing process automation system to SMARs new SYSTEM302-7 using Foundation HSE as the back-bone bringing others protocols to the same Configuration Language. The SYSTEM302-7 is based on the approach to control with the most advanced technology and still protecting their investments. The User can still have conventional instrumentation, and at the same time putting it on a path to the latest advances in the Process Control arena

Integrating New and Existing Equipments

We service existing Ethanol plants seeking to eliminate the constraints of a proprietary platform and gaining the freedom to choose best-in-class automation products from different suppliers. Many of our North-American customers are looking for solutions to integrate new and existing instrumentation, wiring and control hardware and providing a manageable path to the latest technology.

The expansion requires an automation vendor capable of installing, commissioning and supporting a state-of-the art Fieldbus, Hart and Profibus control system implemented at a flexible pace.

Thanks to fieldbus technologies, PID algorithms can now be located in field devices for more secure, reliable control closer to the process. Operators have a user-friendly, Web-enable HMI integrating new and existing automation systems across the facility, as well as trending capabilities enabling tighter control of operations. Significant cost savings were realized by not having to replace existing wiring, enclosures and field equipment when installing the fieldbus system.

With SMAR SYSTEM302-7 Enterprise Automation interoperable with FOUNDATION Fieldbus, Profibus or Hart protocols Ethanol Plants around the globe are assured of a secure, affordable migration path to modern control technology that will be supported by a leading automation supplier for many years to come.

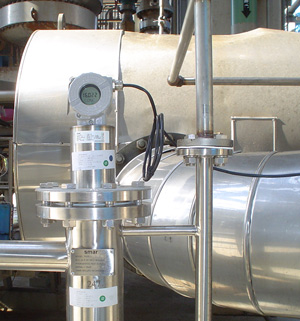

SMAR Density and Concentration solution provides higher accuracy to the industry

BRIX MEASUREMENT OF:

- FEEDSTOCK JUICES

- MUST

- SYRUP

- MOLASSES

- SOLVED JUICES

- BAUM CALCIUM SOLUTION

- HEXANE CYCLE INTERFACE LEVEL

- LIME DENSITY

- HYDRATED ALCOHOL INPM DEGREE

- ANHYDRID ALCOHOL INPM DEGREE

- Accuracy + 0.0004 g/cm3 ( + 0.1 oBrix )

- Range 0.5 g/cm3 - 5g/cm3

- Direct density or concentration readout in engineering units such as g/cm3, kg/m3, Specific Gravity, oBrix, oBaume, oPlato, oINPM, oGL, oAPI,

- % Solids, % Concentration, etc.

- Integral Temperature Sensor

- Suitable for Tank and Pipe Applications

- Factory Calibration and Self Calibration

- Advanced Diagnostics

- Largest Library of Function Block Execution Capacity

- Industrial and Sanitary Models

- Instantiable Function Blocks

- Supported by FONDATIONTMFieldbus, Hart,

- Profibus, EDDL, FDT/DTM, DD

- Density, Concentration and Temperature in three

- Analog Input Blocks

The bottom-line with SMAR: Increased production capacity. Lower operating costs, improved regulatory compliance, and greater profitability.

How? Its Simple...

The modularity of the SMAR control system permits incremental implementation and provides an easy approach to modify and expand the individual control loop strategies in a simple and unprecedented manner to improve feedstock conversion efficiency.

Control systems in existing facilities, have been supplied and installed using conventional DCS (Distributed Control Systems) or PLCs (Programmable Logic Controllers) to satisfy basics process control requirements.

SMAR provides Control Distribution, System Configuration, Asset Management and System Documentation all available in one, easy-to-use, integrated control system - yet interoperable with all major protocols and yet, with technology from other suppliers, SYSTEM302-7 simplifies your automation decisions. This OPEN, scalable solution is designed to protect your installed assets and co-exist with legacy systems.

FACTS

MAKING 30 YEARS OF ETHANOL HISTORY.

Since the early 70s SMAR has been fortunate to have helped numerous clients, to better understand, manage, use and develop new technologies. Ethanol Plants have proven to have benefited from our services and products.

BEING PRESENT IN OVER 90% OF ETHANOL FACILITIES.

SMAR has taken a major role in this achievement providing Services and first class Instrumentation and Control Devices for Ethanol Plants. This partnership with producers brings performance with higher profitability, superior quality and the understanding of the business really make the difference.

SETTING STANDARDS TO THE INDUSTRY.

SMAR pioneered many of todays Automation and Instrumentation technologies available for the Ethanol and Bio-Diesel. Our long term experience in these sector can provide various optimizations of your entire plant.

PROVIDING OPEN SOLUTIONS AND LEGACY.

Users around the world have discovered the freedom SMAR can provide. SMAR works with recognized technologies; 4-20mA, Hart, Foundation Fieldbus, Profibus, Modbus, OPC and others.

By selecting interoperable technologies, you dont need to commit to an exclusive manufacturer. In the same regard, devices from different brands, using the same protocol, can coexist on the same bus. SMAR gives you the freedom to chose!

DIVERSIFIED RANGE OF APPLICATIONS.

Oil and Gas (including offshore), U.S Navy, Food Processing, Nuclear Plants, Pulp and Paper, Chemical Industry, Sugar, Ethanol, Hydro and Fossil Energy, Water and Wastewater are just a few examples of our diversification.

HAVING THE BEST WAY TO UPGRADE TO NEW TECHNOLOGIES.

SMAR makes it easier to move between HART, Foundation Fieldbus and Profibus without buying any new field devices. Changing technologies is as simple as changing an electronic board or in some cases only downloading a new firmware. SMAR also offers a line of Converters that can integrate your existing legacy platform to modern technologies.

Latest news

-

Nova Smar holds PATS in Pindamonhangaba/SP

-

Basic instrumentation training for new employees

-

Nova Smar takes part in Meorga Frankfurt 2024

-

Nova Smar took part in the 28th ARC in Orlando

-

Revide magazine mentions Nova Smar in article on Sertãozinho

-

Training at Zilor Plant - Macatuba unit

-

Flow computer upgrade

-

Training at the Zilor Plant Quatá

-

Training at Dacalda Sugar and Alcohol

-

System302 CPU800 training