Sugar and Ethanol producer Caete Distillery reports savings and increase productivity with Foundation Fieldbus - HSE technology by SMAR

BACKGROUND

Caeté-Matriz Distillery is among the world top 10 sugar and ethanol plant producer acquired by the internationally known Carlos Lyra’s Group located in Alagoas, Brazil.

Initially, this sugar and ethanol plant was automated using the 4~20mA/HART communication protocol. Later on, as the plant production had increased and new communication protocols were defined, a new process area was designed using Foundation Fieldbus technology.

Consequently new technologies were applied for the plant automation, in which the Profibus protocol became an alternative for classified and MCC areas (Motor Control Center). This service article describes how SMAR’s SYSTEM302-7 simplified Caete Distillery automation decisions, with an opened and scalable solution designed to protect installed assets and co-exist with other legacy systems, using also Foundation Fieldbus - HSE infrastructure, and yet interoperable with all major protocols.

PLANT CONTROL ARCHITECTURE - Modern Automation Solution

Caeté-Matriz plant automation process supervises and controls a large number of field devices variable from several manufacturers and different technologies. SYSTEM302-7 is an open and networked distributed control system that provides integrated tools to configure, operate, maintain and optimize industrial facilities.

It is designed in client/server schema and allows the multi-user environment. This concept provides more flexibility, power and velocity in all activities concerning the plant’s lifecycle and additionally reducing the project delivery time.

Regulatory and discrete control strategies were created and executed in the same process controller using the Flexible Function Block concept. This unique feature is available through out the DFI302, the SYSTEM302-7 control platform, in which also incorporates its workplace tool called STUDIO302

During the project configuration stage Syscon, the fieldbus configurator tool has provided full access to the fieldbus networks. Further, this platform makes available the AssetView, the system component responsible to manage plant assets and diagnostics, generating alarms and maintenances for the field devices. All of the plants information management is controlled with reliability and accuracy needed with SMAR- Studio302.

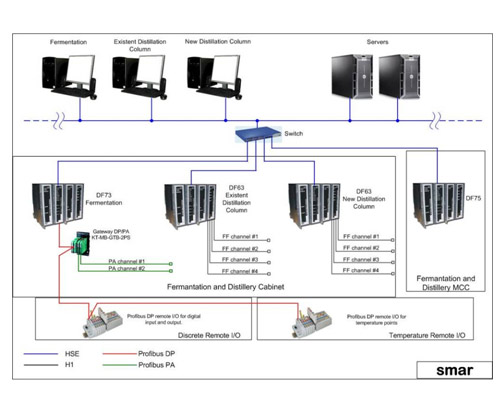

Figure 1 – Caeté Plant Architecture.

In compliance with client standardization, all plant supervision has been performed by GEFanuc-HMI/Scada Cimplicity using redundant database servers communicating with the controllers via OPC technology, in which, was selected by plant’s management as a better communication performance due to its open standard for data transferring in real time at the most considerations of:

- Standard communication interfaces between clients and servers in real time data transfer, providing easy system integration and maintenance;

- Specific communication drivers are not necessary;

- Performance improvement and communication optimization between automation field devices;

- Interoperability among systems from different manufacturers;

- Integrated to MES, ERP and windows applications;

- Time and costs reduction. It eliminates interfaces and communication drivers development, hence reducing system integration overall costs;

- Easy to develop and maintenance systems and products for real time communication;

- Easy to learn.

Integrating New and Existing Equipment

Although a series of upgrades may occur, Carlos Lira’s Group decided to keep all LC700 Systems (SMAR PLCs) in the Juice Treatment and leaving the option to replace these controllers for a DF75 HSE Ladder Processor available in the SMAR-DFI302 series for a future system upgrade.

The Fermentation Process uses the SMAR-DF73, a DFI302’s controller that is a Profibus DP master and HSE RIO at the same time. It is responsible for controlling the entire process by automatically injecting defoamers and back washing the fermentation tank’s heat exchangers.

A Profibus PA slave module from Wago has been used to activate solenoids, accessed by the SMAR-DF73 through the SK3 set by Pepperl+Fuchs DP/PA coupler

The HSE Foundation Fieldbus controller SMAR-DF63 is responsible for the entire ethanol distillation process. Caeté-Matriz Distillery has used the previous DF51 Foundation Fieldbus Bridge to operate and, therefore the client preferred to maintain H1 protocol and upgrade the Linking Device in order to provide HSE connectivity and complete redundancy.

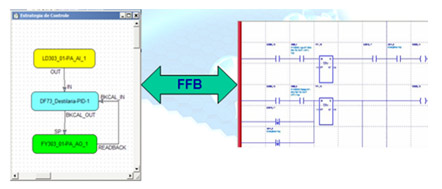

Figure 2 – HSE Controllers in the DFI302 Series

New SMAR DFI302 controllers have native and redundant HSE (High Speed Ethernet) connections, providing twin 100Mbit/s Ethernet connectivity. Flexible Function Blocks (FFB), available in HSE controllers provides data between analog and discrete controls. Using FFB, it is possible to create HSE links between controllers. Therefore, analog control is totally integrated to discrete control.

Figure 3 – Analog and Discrete Control Integration

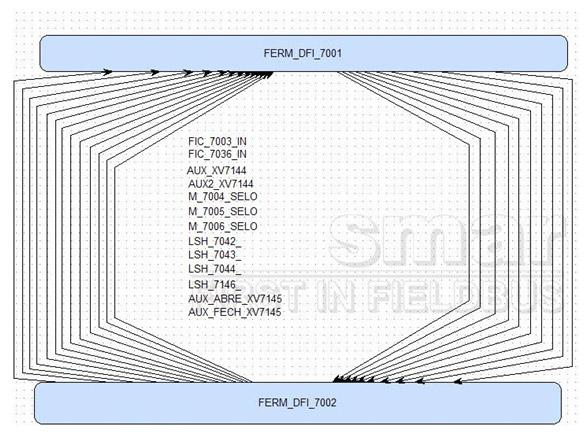

Using HSE protocol, controllers in the Caeté-Matriz Distillery plant can exchange information using the HSE links.

Figure 4 – HSE Link implemented in Caeté

Caeté-Matriz Distillery also required exchanging data between controllers. For instance, it was necessary to interlock a fermentation tank high level signal, provided by a Profibus PA transmitter connected to the SMAR-DF73, to the FF RIO’s solenoid in the Juice Treatment. The PA level transmitter’s signal has been transferred directly to the Foundation HSE RIO’s solenoid via HSE link.

In another situation, data is exchanged between the SMAR-DF73 Profibus Master and the DF75 Ladder Processor to activate the most pumps which is connected to the DF75, only when the back wash control is started.

The figure below illustrates controllers assembled in Caeté-Matriz’s Plant control cabinet.

Figure 5 – Cabinet with DFI302 Profibus Master HSE RIO (SMAR-DF73), Gateway DP/PA and DFI302 Foundation fieldbus HSE RIO (SMAR-DF63).

Figure 6 – Cabinet with SMAR-DF75 Ladder Processor and conventional I/O modules.

Results

Caete Distillery faced a tight schedule for upgrading its process control system to coincide with plant expansion - production demands would not allow for lengthy downtime for installing new equipment. Design of the control system began in May 2007, and commissioning and startup of the first and second phases were completed in September 2007 and May 2008, respectively.

Thanks to fieldbus technology, PID algorithms are now located in field devices for more secure, reliable control closer to the process. It may be further mentioned HSE infrastructure makes available a new range of applications once it integrates different technologies in a unique system. Operators have a user-friendly, Web-based HMI integrating new and existing automation systems across the facility, as well as trending capabilities enabling tighter control of operations. It is estimated 30% of significant cost savings by not having to replace existing wiring, enclosures and field equipment when installing the fieldbus system.

Conclusion

Caete Distillery is assured of a secure, affordable migration path to modern control technologies that will be supported by leading automation suppliers for many years to come.

SMAR provided a robust distributed digital control system based on Foundation Fieldbus - High Speed Ethernet that supported multiple controllers, open and scalable integration, interoperable with FOUNDATION fieldbus, Profibus and Hart devices in which increased project feasibility from the plant upgrade to its new architecture.

SMAR-SYSTEM302-7 was selected as the best-in-class platform to deliver all features required by Caete plant; it is also identified as the major responsible source for the plants automation and control success. “We’re taking full advantage from the three different technologies, today and its process is capable to expand in the future with no restraints - SYSTEM302-7 assures plant’s expansibility, since it is designed with a totally open HSE infrastructure - states Maurício Veras – Caete Distillery – Electrical Engineer and Corporate Automation Manager of Carlos Lyra’s Group.

About the Authors

Edinardo Mariano Magalhães de Souza – is a Senior Applications Engineer for SMAR with BSEE from UNESP – São Paulo State University.

Leandro H. B. Torres – is a System and Solutions Manager for SMAR Group. Prior to joining the SMAR team, he spent 5 years as a Chemical and Petrochemical Applications Engineer. Torres also has a BSEE from UNESP – São Paulo State University.

Latest news

-

Nova Smar holds PATS in Pindamonhangaba/SP

-

Basic instrumentation training for new employees

-

Nova Smar takes part in Meorga Frankfurt 2024

-

Nova Smar took part in the 28th ARC in Orlando

-

Revide magazine mentions Nova Smar in article on Sertãozinho

-

Training at Zilor Plant - Macatuba unit

-

Flow computer upgrade

-

Training at the Zilor Plant Quatá

-

Training at Dacalda Sugar and Alcohol

-

System302 CPU800 training