New TT383 - Eight Input Temperature Transmitter with Profibus PA

|

Eng. Pablo Batch |

|

INTRODUCTION

Temperature measurement is one of the most common applications in any industrial plant. Usually it is demanded with a large number of points to be measured, and the best added-value to the process.

SMAR temperature transmitter’s Family is growing and now we proudly present the new TT383. It is the only Profibus PA 8-channel temperature transmitter in the global market, and its technology brings reliability, cost-effectiveness and accuracy for field applications.

ABOUT TT383

The new TT383 has 8 independent inputs for RTDs, Thermocouples and mV / Ohms signals. Each channel has 0.03% of accuracy, and it is powered through the same Profibus PA communication bus where the equipment is connected. The TT383 is also available for intrinsic safety applications.

One of the great TT383 advantages is that only one node on Profibus network is required, and the equipment can manage up to eight independent temperature points. Therefore, power consumption and logic nodes in network are optimized.

TT383 has an aluminum enclosure, lightweight and compact, and occupies less than 4 inches in a rail mounting. There are also removable terminal blocks for sensor connection, for user convenience.

TT383 configuration can be done by using any software with FDT/DTM Technologies (PACTware, FieldCare, Asset View, and others), or via Simatic PDM from Siemens.

SENSORS

RTD sensors can be connected with 2 or 3 wires, and with TCs the TT383 compensates automatically the temperature because of the cold junction.

TT383 inputs can be configured in all of these ways:

- Simple measurement: each sensor corresponds to a single measure;

- Differential: The output is the difference between two sensors’ outputs;

- Sensor backup: when a sensor breaks, TT383 changes the data acquisition to other automatically.

FLEXIBILITY IN APPLICATIONS

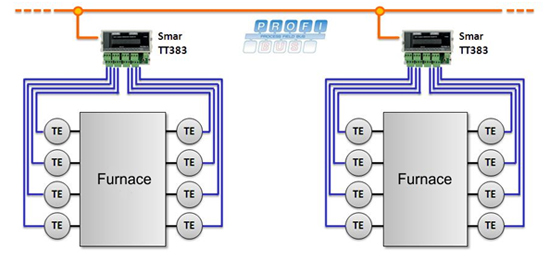

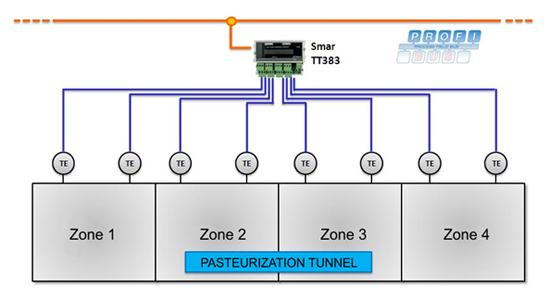

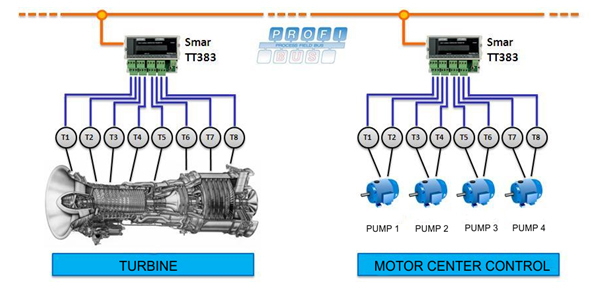

TT383 is indicated for applications where several points for temperature control or monitoring must be integrated to Profibus network, as indicated below:

furnaces and Distillation Towers

Pasteurization Tunnels and Cooling

Turbines Monitoring or Motors in MCCs

SAVES IN PROFIBUS NETWORK ADDRESSES

Up to eight points can be saved in the Profibus network, when DP links are not being used. In configurations like PLC plus DP/PA couplers and speed couplers it can be very useful, and also cabling, manpower and other resources will be saved.

TT383 can also be used to integrate temperature sensors which are installed in conventional systems that will be updated to Profibus technology. TT383 will be an intelligent Profibus PA remote I/O for temperature signals.

FEATURES

- 8-channel temperature transmitter

- Profibus PA Technology

- Intrinsically Safe

- Uses only one node on the Profibus PA network

- Easy network addressing via physical switches,

- ± 0,03% accuracy,

- Thermocouples, RTDs, mV and Ohm sensors,

- Single, Differential and Backup measurement,

- 2 and 3 wires connection,

- Supports DD/EDDL and FDT/DTM technologies

- Compact, lightweight and rugged

- DIN rail mounting