Profibus-PA use remote inputs and outputs to help automate control systems processes

Introduction

In a previous article we examined how to execute logics on a Profibus-PA equipment in hybrid systems with the DC303 – Remote Inputs and Outputs for panels, including the possibility of dealing with discrete inputs and outputs, and logic and sequential control.

Now we will examine some details on the most recent information on the use of the Profibus-PA technology for the discrete activation of equipment connected directly to the bus on small and medium-size applications. This article show details on the FRI303 for Remote Inputs and Outputs, a Profibus-PA field equipment.

This development easiness was mostly due to microprocessors and microcontrollers technological innovations.

The technological progress in the microprocessor and microcontroller area and the current scenario of automation technologies

In the last few years the instrumentation and automation markets have demanded field equipment (pressure and temperature transmitters, converters, positioners, actuators, controllers, etc) with high performance, reliability, availability, resourcefulness, etc, aiming at minimizing economic consumption, reducing process variability and obtaining the reduction of operational and maintenance costs, as well as guaranteeing process optimization and improvement.

On the other hand, microprocessors and microcontrollers are becoming more powerful and less expensive, while instrumentation suppliers have responded to the demand for more and better information in their processes. The more information, the best operated a plant can be and more products and profits are generated. Digital information allows a system to collect information for a plant most diverse types and purposes, as never imagined before. And, in this sense, the advent of the Fieldbus technology (HART, Profibus, Foundation Fieldbus) may turn precious bits and bytes into a profitable relationship and also improve the entire system quality.

The Fieldbus technology supplies rich information not only pertinent to the process but especially to the field equipment. So, self-diagnostics conditions may save operational and maintenance costs, chiefly in hazardous areas or even those difficult to reach. From the control room there is a general view of the system any time, any place, with Internet-based tools. By managing the field information, it is possible to conveniently select data to meet the production objectives, direct the information to the right persons and departments and help boost the entire process.

All this technological evolvement made field equipment to take over unthinkable new functions, such as discrete and continuous control, shorter scanning time, redundant architectures, information and traffic managing, availability of IHM information, Internet, generation of reports, asset management, high safety levels, etc. Everything combined to reliable hardware and software for industrial work.

Next we will see details on the FRI303, microprocessed field equipment with discrete input and output blocks, a true example of automation advancement through the use of micro-processors.

FRI303, discrete on-field inputs and activation via bus

.jpg)

Figure 1 –SMAR FRI303

The FRI303 provides easy integration between the Profibus-PA and conventional discrete inputs and outputs. Discrete devices such as on/off sensors, on/off valves, pumps, conveyor belts and electrical actuators, speed variators, etc. can be integrated to the Profibus system via PA bus, using the FRI303. It may also be distributed to the field conventional discrete devices without the need of wiring from the control room.

The FRI303 allows that conventional discrete and analog inputs and outputs are easily configured on control strategies using Functional Blocks and homogenizing the system so these devices look like a simple fieldbus bus diapositive. It has two DI and DO functional block pairs.

Control loops are implemented independently whether conventional I/O type or Profibus devices.

.jpg)

Figure 2 – Generic application with discrete input and output

FRI303 Functional Diagram

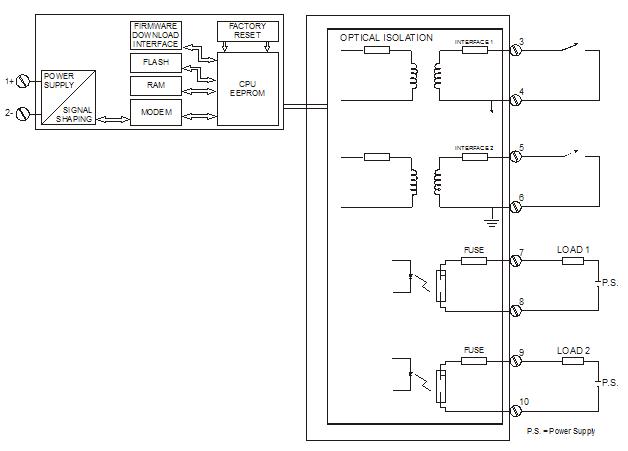

Figure 3 shows FRI303 the functional diagram and figure 4 shows the output physical connection

Figure 3 – FRI303 functional diagram

Characteristics

- 3optional outputs:

- 2 contacts in normally closed (NF) solid state relays,

- 2 contacts in normally open (NA) solid state relays, and 1 NF and 1 NO

- Inputs: 2 dry contacts

- DI and DO Functional Blocks

- Friendly firmware update

- Date saving of data during shutdown

- Power Supply: Via Profibus-PA: 9-32Vdc, quiescent current consumption: 17mA

.jpg)

Figure 4 – Output physical connection

Physical Connection with DI and DO Functional Blocks

Through two Digital Output (DO) and two Digital Input (DI) functional blocks you may command two DC or AC loads and read two digital inputs. The DI Block uses discrete input data selected via channel and enables it for another functional block use through its output. The DO functional block converts the SP_D value to a value useful to the hardware through the selected channel

.jpg)

Figure 5 – Physical Connection with DO blocks

Application Example: Level Control

Suppose that a Profibus network enables the discrete signal of level alarm via discrete inputs to the FRI303 on the DI blocks. When a determined level value is reached through a DO block, the pump that feeds the tank can be switched off and turned on again as soon as the lower level is lower than the configured limit. See figure 6.

.jpg)

Figure 6 – FRI303 application in level control

Conclusion

This article showed how important is the microprocessors technical progress in automation and process control, as well as details on a micro-processed equipment for startup and reading discrete values.

References:

1. SMAR Profibus manuals

2. FRI303 Operation manuals

4. Issued on https://www.smar.com/en

15/03/2012 4:12:38 PM